Sheep Manure Composting Fertilizer

Sheep manure composting and granulating for organic fertilizer can not only assist in efforts to follow livestock waste disposal regulations, but also create a potential new source of revenue, making it a win-win proposition.

The sheep manure discussed here not just contains the urine and feces from sheep, but also the bedding, runoff, spilled feed, and anything else mixed with it. It is a way of decomposing sheep or goat manure waste to create a fine and rich humus material that is applied as a soil amendment and plant nutrient. Utilizing sheep manure properly - composting sheep manure fertilizer is an advantageous tool in nutrient management way because sheep manure organic fertilizer can not only reduce the potential to pollute and benefit the crops.

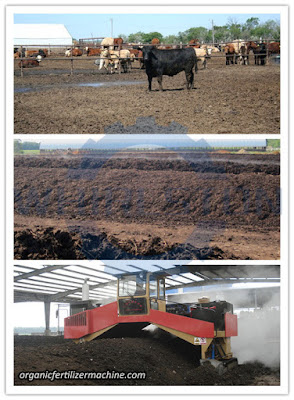

Parasites, hormones, and other pathogens contained in sheep manure can be reduced by proper composting. Odors are reduced and fly eggs die due to the high temperatures occurring during microbial decomposition. Making good compost needs the proper balance of carbon and nitrogen, keeping the pile of compost moist and adequate aeration. The ratio of carbon to nitrogen is critical to the composting process. The ideal ratio is about 30 parts carbon to 1 part nitrogen. Using Whirlston compost turner machine to turn the compost pile will keep it aerated and speed up the composting process. Sheep manure wastes typically take several days to two weeks to finish the compost in long open piles.

Sheep manure without granulation is difficult and costly to transport. Additionally, the quality and nutrient content within unprocessed manure may vary greatly, making it difficult to properly treat soil and yield optimal results. Sheep manure composting and granulating for organic fertilizer can not only assist in efforts to follow livestock waste disposal regulations, but also create a potential new source of revenue, making it a win-win proposition. After composting, send the mixed sheep manure raw materials into the granulation system - a professional new-type organic fertilizer granulator, processing for spherical particle organic fertilizer. Then use the conveyor to transport granules into dryer, next entering the cooling system after drying process. The granulated organic fertilizer will be at room temperature when starting screening, and the particles would be packaged after meeting the requirements of screening machine. Those do not meet the requirements would be returned to granulation system, continue to granulate. The granulating process of sheep manure creates commercial organic fertilizer, which is easy to package, transport and sale.

The sheep manure discussed here not just contains the urine and feces from sheep, but also the bedding, runoff, spilled feed, and anything else mixed with it. It is a way of decomposing sheep or goat manure waste to create a fine and rich humus material that is applied as a soil amendment and plant nutrient. Utilizing sheep manure properly - composting sheep manure fertilizer is an advantageous tool in nutrient management way because sheep manure organic fertilizer can not only reduce the potential to pollute and benefit the crops.

Parasites, hormones, and other pathogens contained in sheep manure can be reduced by proper composting. Odors are reduced and fly eggs die due to the high temperatures occurring during microbial decomposition. Making good compost needs the proper balance of carbon and nitrogen, keeping the pile of compost moist and adequate aeration. The ratio of carbon to nitrogen is critical to the composting process. The ideal ratio is about 30 parts carbon to 1 part nitrogen. Using Whirlston compost turner machine to turn the compost pile will keep it aerated and speed up the composting process. Sheep manure wastes typically take several days to two weeks to finish the compost in long open piles.

Sheep manure without granulation is difficult and costly to transport. Additionally, the quality and nutrient content within unprocessed manure may vary greatly, making it difficult to properly treat soil and yield optimal results. Sheep manure composting and granulating for organic fertilizer can not only assist in efforts to follow livestock waste disposal regulations, but also create a potential new source of revenue, making it a win-win proposition. After composting, send the mixed sheep manure raw materials into the granulation system - a professional new-type organic fertilizer granulator, processing for spherical particle organic fertilizer. Then use the conveyor to transport granules into dryer, next entering the cooling system after drying process. The granulated organic fertilizer will be at room temperature when starting screening, and the particles would be packaged after meeting the requirements of screening machine. Those do not meet the requirements would be returned to granulation system, continue to granulate. The granulating process of sheep manure creates commercial organic fertilizer, which is easy to package, transport and sale.

Comments

Post a Comment